Laboratory Research

(LR-045) Smart Solutions for Wound Care: Technology with Hybrid Printed Electronics

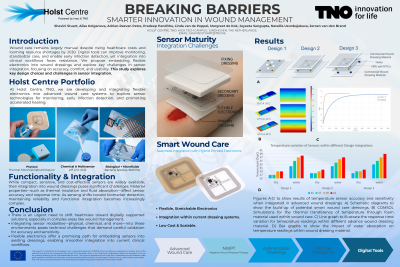

Chronic and infected wounds that fail to heal are emerging as a silent epidemic in the healthcare system. Historically, wound management has progressed at a slow pace, with significant advancements occurring only every few decades. This slow pace of innovation must accelerate to address growing challenges. With a projected decline in experienced medical practitioners by 2030 and a rise in populations vulnerable to chronic wounds, the need for standardized, scalable wound monitoring is more critical than ever.

Digital tools present a transformative opportunity with the use of Hybrid printed electronics (HPE) which enables flexible, cost-effective and scalable, sustainable wound management solutions through seamless integration within current dressings.

Challenges remain however for bridging the gap between technology and healthcare with sensors required to deliver reliable functionality while ensuring wearability and comfort over extended periods.

This study investigated the integration of physical temperature sensing and chemical pH sensing to assess their impact on sensor performance and overall dressing functionality.

Methods: Hybrid printed electronics (HPE) was used to fabricate two sensor modalities; a temperature sensor matrix using negative temperature coefficient thermistors (NTC’s) and a potentiometric PH electronic components. The use advanced wound dressing material in the form of hydrocolloid or super absorptive foam was used within a laboratory set-up using a hot-plate with heated PH solutions.

Results: The findings highlighted that dressing material properties—such as insulation and the ingress of wound exudate—significantly influence sensor sensitivity and accuracy. The impact of refresh rate for chemical sensors, sensor drift and interference molecules showed high impact for chemical sensors. While for temperature sensors, the placement of the sensors within the material showed a high impact for sensor accuracy and response time with increased water ingress.

Discussion:

Future advancements in sensor design could prioritize positioning sensors in a 3D configuration across multiple depths within the dressing or embedding them in matrix structures within multisensory embodiments to achieve more precise calibration. Such innovations have the potential to transform wound care by offering deeper, more accurate insights into the complex and non-homogeneous nature of wounds.

.jpg)